Spring Types

- There are two basic types of spring used in garage doors Tortion Springs and Extention Springs

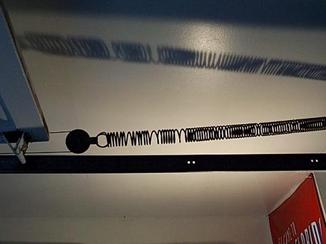

Extention Springs

These springs run alongside the tracks along the rail 2 pulleys on the other end lift the door. the spring pictured is missing the safety cables. if this spring or its cable broke the spring would fly through the air at a great speed hitting a car or person. An extention spring can only break with the door down. so it is likely to happen when a person is raising or lowering the door. Safety cables are essental to avoid damage to people or vehickles

-

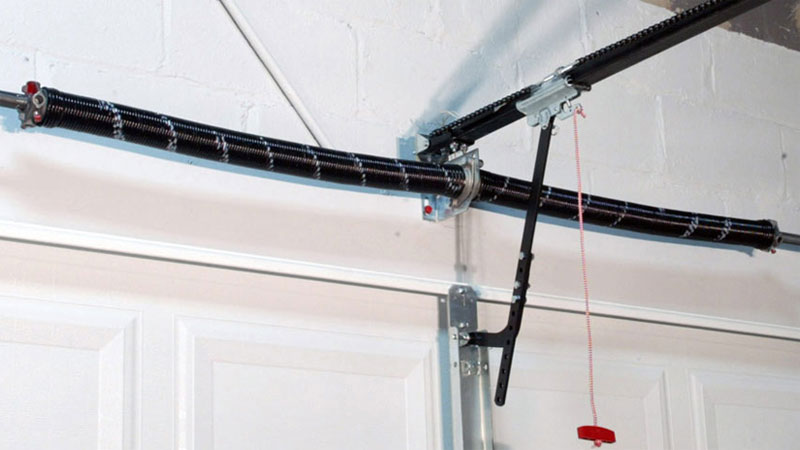

Torsion Springs

- These springs are wound atop the door on a steel shaft, and special tapered cones lift the door.The springs and cones are designed to work together to equalize the lift as the door gets lighter as weight is supported by the tracks paralell to the floor. On torsion springs no safety cables are required as the spring is confined to the shaft.

Spring

Facts you need to know

Both Types of spring do the same job, lifting the door.

Extension springs come in two lengths for 7 foot and 8 foot doors. They also come in different lifting weights identified by the color on the end of the spring. The springs are graduated in 10 pound increments according to color, so a red spring can be either 150 pound or 250 pounds according to the wire gauge it is made of. A door must use the correct spring or it will ruin the opener or the person operating the door. Often springs replaced by a homeowner will come un marked from a hardware store making it dificult to replace the problem spring with a correct one. Even 20 or 30 pounds off can do a lot of damage and make a door a bear to open. a spring too strong is called a "hot" door and one too weak "runs heavy"

If the spring, for what ever reason, was incorrectly replaced it is necessary to weigh the door with special scales. This is especally true for wood doors weighing more than 250 pounds.

Both types of spring are rated in cycles. A cycle is one open and one close. The minimum number of cycles for any spring is 10,000, This means if a door is opened and closed once a day it would last 27 years! Unfortunately we use the door at least 4 times a day reducing that to about 12 years. Some families use the garage as the main entrance and can burn through 10 cycles a day!  The spring above is showing signs that it is ready to break. As the metal in the spring bends it gets stiffer and less flexible, eventually it will crack at one of these points. Again, this spring is an accident in the making as it has no safety cable.

The spring above is showing signs that it is ready to break. As the metal in the spring bends it gets stiffer and less flexible, eventually it will crack at one of these points. Again, this spring is an accident in the making as it has no safety cable.

Torsion springs can be engineered by using different length and wire diameters and size of the coil in the spring in Combinations that give longer cycle life to the spring and still lift the same weight. All Family's policy is to engineer replacement springs to have at least 20,000 cycles. This assumes the shaft is long enough to accept the longer springs. Torsion springs expand and contract like an accordion making it necessary to stretch them a minimum 2 inches to keep coils from rubbing on themselves. It is important not to use guesswork matching this type of spring . do not believe some one who says he has every spring "on the truck". Because cycle life is pretty much the same, broken springs should always be replaced in pairs. torsion springs require some maintenance and should be oiled or lubricated with silicone at least once a year. Extension springs do not require oil.

All springs are not equal!

How and where a spring is bent at the end is important .Hardware store springs are simply bent at the last coil leaving a stressed area at the bend that usually causes the break.

A quality spring has a jig that koops the end twice around and gently curves it out of the coil. Ideally the spring is tempered after the end is bent.